Application area

Sonacme Technology's ozone aging test chamber is mainly suitable for the ozone aging resistance test of polymer materials and their products.

The ozone aging test chamber simulates and strengthens the ozone conditions in the atmosphere, and obtains test results similar to actual use or reproducibility in a short period of time, to study the effect of ozone on polymer materials and their products (rubber), and to quickly identify and evaluate rubber The method of anti-ozone aging performance and anti-ozonant protective effect, and then take effective anti-aging measures to improve the service life of rubber products.

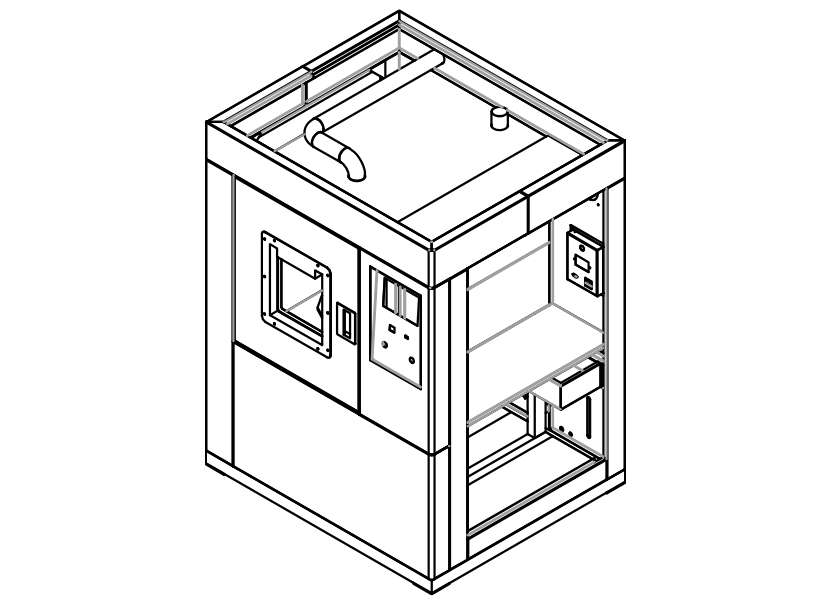

The inner chamber material is made of SUS#304 stainless steel with 1.2mm thickness. Full welding structure, its sealing is very well and it’s not easy to get cracked.

The external material is made of cold-rolled plate with 1.5mm thickness, it has gone through brushing, polishing, painting treatment, it's not easy to get scratched.

The insulation material is made of polyurethane foam with thicknessof 100mm.

The door seal adopts double silicon rubber sealing material.

The observation window is 4 layers of tempered glass, the size you can choose by yourself.

In addition, in order to prevent frosting on the observation window when running low temperature, we setup a heating wires inside to get it di-frosting.

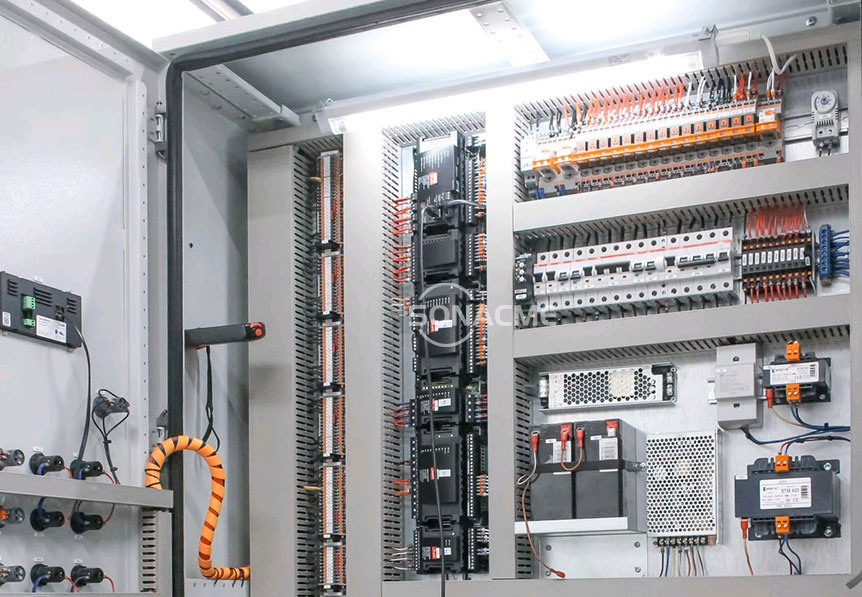

The overall layout of the circuit cabinet looks very neat and professional. Our circuits are arranged in accordance with UK standards and are equipped with complete circuit diagrams. Each line has a unique code which is clearly defined and easy to locate for troubleshooting.

We use electrical components of world famous brands, such as Schneider from France, Carlo Gavazzi from Switzerland,Mitsubishi from Japan,Rainbow from Korea.

| Model | SO/150 |

| Inner chamber size(mm) | 500(W)*600(H)*500(D) |

| Outer chamber size(mm) | 1150(W)*1500(H)*750(D) |

| Temperature range | RT+10~+60℃ |

| Ozone concentration | 0~1500pphm (adjustable) |

| Ozone concentration deviation | ≤10% |

| Power supply | 3~5KW |