Application area

The high, low temperature and low pressure altitude test chamber (temperature/altitude) is designed to allow users to perform temperature and altitude condition tests in a combined test chamber, and create multiple conditions to meet multiple test requirements at the same time.

For the test application of satellites, rockets, airplanes or helicopters: modern airplanes are subject to great pressure during use. We provide prefabricated and customized low-pressure test chambers for ultra-low cooling and extended temperature range to meet your exact test requirements.

The low-pressure test chamber is also designed to meet many stringent MIL STD and RTCA test requirements. Sonacme Technology provides high and low temperature and low air pressure test chambers for simultaneous temperature/altitude testing from on-site altitude to 65,000 feet.

DEF STAN 0035 3-11 (High temperature, low pressure)

DEF STAN 0035 3-12 (High temperature, low pressure)

DEF STAN 0035 3-13 (low temperature and pressure)

MIL-STD-810G METHOD 500.5 Procedure I

MIL-STD-810G METHOD 500.5 Procedure II

MIL-STD-810G METHOD 500.5 Procedure III

RTCA/DO-160C

The inner chamber is fully welded from 2mm thick SUS304 stainless steel plate. The advantage of full welding is that it has good sealing and is not easy to crack.

The outer wall adopts 10mm thick HRS steel plate, and adopts a detachable plate structure in the appropriate position, which is convenient for future maintenance and repair of the insulation interlayer of the cabinet; the metal plate is cleaned and treated with corrosion-resistant and anti-rust paint.

The insulation material is made of polyurethane automatic mechanical foaming, and the thickness of the insulation layer is 150 mm.

The door is sealed with double-layer silicone sealing material, which has a good sealing effect.

The inner chamber is fully welded from 2mm thick SUS304 stainless steel plate. The advantage of full welding is that it has good sealing and is not easy to crack.

The outer wall adopts 10mm thick HRS steel plate, and adopts a detachable plate structure in the appropriate position, which is convenient for future maintenance and repair of the insulation interlayer of the cabinet; the metal plate is cleaned and treated with corrosion-resistant and anti-rust paint.

The insulation material is made of polyurethane automatic mechanical foaming, and the thickness of the insulation layer is 150 mm.

The door is sealed with double-layer silicone sealing material, which has a good sealing effect.

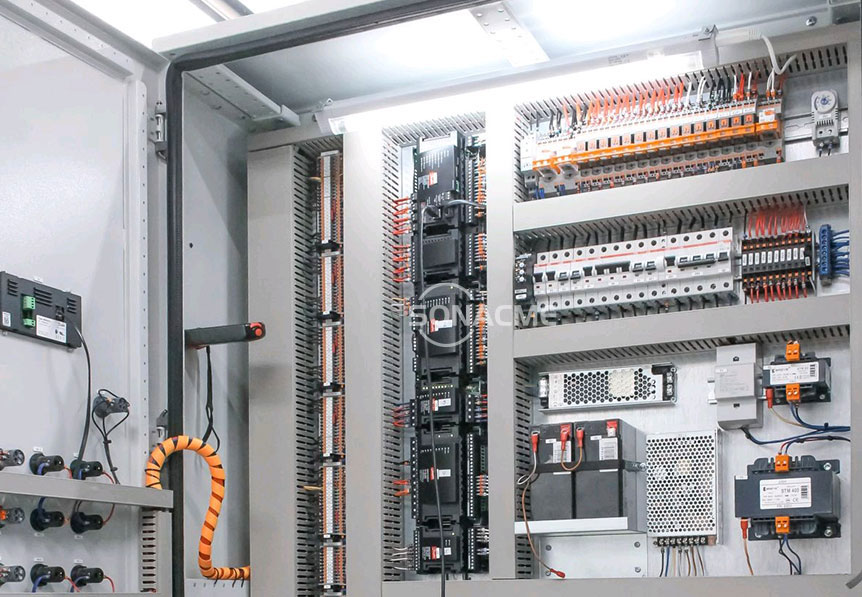

The overall layout of the circuit cabinet looks very neat and professional. Our circuits are arranged in accordance with UK standards and are equipped with complete circuit diagrams. Each line has a unique code which is clearly defined and easy to locate for troubleshooting.

We use electrical components of world famous brands, such as Schneider from France, Carlo Gavazzi from Switzerland,Mitsubishi from Japan,Rainbow from Korea.

| Model | SAT/250/70(H) | SAT/500/70(H) | SAT/1000/70(H) | SAT/2000/70(H) |

| Volume | 250L | 500L | 1000L | 2000L |

| Internal Dimension W*H*D(mm) | 550*600*700 | 700*800*900 | 1000*1000*1000 | 1400*1200*1200 |

| External Dimension W*H*D(mm) | 2000*1060*1900 | 2500*1260*2050 | 2720*1460*2130 | 3150*1650*2050 |

| Temperature Control Range | -70℃~180℃ | |||

| Humidity Control Range | 20.0%RH~98.0%RH ( work under atmospheric humidity) | |||

| Pressure range | Normal pressure ~ 0.5kpa(500pa) | |||

| Safety | Adjustable over temperature protection, heater dry burning over temperature protection, humidifier dry burning, over temperature protection, automatic stop operation when troubles occur. Leakage protection function cuts off main power supply | |||

| Power supply | 380V AC 50/60Hz | |||