Application area

The Walk in Xenon lamp Test Chamber can reproduce the damage caused by full-spectrum sunlight and rain. Within days or weeks, the walk-in xenon lamp aging test chamber can reproduce the damage caused by outdoor aging for months or years. The walk-in xenon lamp aging test box is a full-featured light stability, color fastness and light fastness test chamber.

When the product is exposed outdoors, the maximum light intensity of direct sunlight is only a few hours a day. The xenon lamp test chamber allows the test sample to be irradiated by the sun at noon in summer, 24 hours a day, every day. Therefore, the sample can be aged quickly.

The Walk in Xenon lamp Test Chamber adopts a xenon arc lamp that can simulate the full sunlight spectrum, reproduces the destructive light waves existing in different environments, and provides corresponding environmental simulation and accelerated tests for scientific research, product development and quality control.

It is recognized by many original equipment manufacturers in the automotive, paint and coatings, and plastics industries as an exclusive platform that provides accurate and repeatable results to predict service life.

The inner chamenr is fully welded by 1.2 mm thick SUS304 stainless steel plate. The advantage of full welding is that it has good sealing and is not easy to crack.

The outer chamber is made of 1.5 mm thick cold-rolled steel plate, which is brushed and polished, and is treated with high-temperature paint, which is not easy to scratch.

The insulation material is made of polyurethane automatic mechanical foaming, and the thickness of the insulation layer is 100 mm.

The door is sealed with double-layer silicone sealing material, which has a good sealing effect.

The observation window is 4 layers of tempered glass, and the size of the window can be customized according to customer requirements.

Compressors equipped with world famous brand such as Tecumseh (France made), Bitzer or GEA BOCK (Germany made).

Shock absorption and noise reduction process,slow down the vibration, protect the compressor.

The new pipe bending technology: The bending process can minimize the connector point and make refrigerant flow more efficiently.

It applies Denmark DANFOSS and Japanese SAGLNOMIYA solenoid valves to improve the overall reliability of the equipment.

MP10 module has motor over-heating protection (with LED indicator), exhaust temperature over-heating protection (requires optional temperature monitoring probe and LED indicator), power indicator, alarm function.

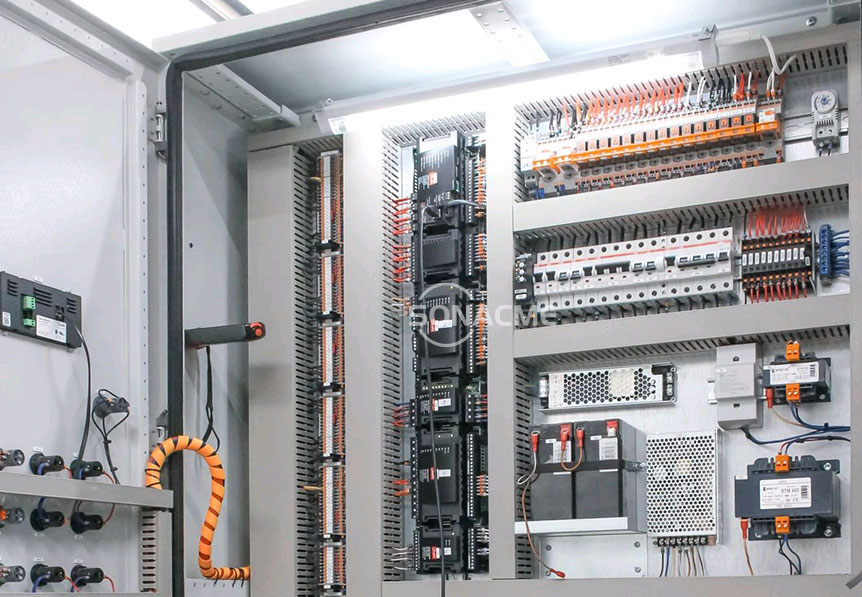

The overall layout of the circuit cabinet looks very neat and professional. Our circuits are arranged in accordance with UK standards and are equipped with complete circuit diagrams. Each line has a unique code which is clearly defined and easy to locate for troubleshooting.

We use electrical components of world famous brands, such as Schneider from France, Carlo Gavazzi from Switzerland,Mitsubishi from Japan,Rainbow from Korea.

| Model | STX/400/H/A | STX/600/H/A | STX/1000/H/A | STX/3600/H/A |

| volume | 400L | 600L | 1000L | 3600L |

| Internal Dimension W*H*D(mm) | 700*850*700 | 850*900*750 | 1000*1000*1000 | 1700*1800*1200 |

| External Dimension W*H*D(mm) | 1350*1850*980 | 1500*1900*1050 | 1650*2100*1300 | 3600*2300*1600 |

| Temperature Control Range | -70.0℃~80.0℃ | |||

| Humidity Control Range | 20.0%RH~98.0%RH( Temperature range without light:10.0℃~85.0℃) | |||

| 20.0%RH~80.0%RH(Temperature range with light:20.0℃~70.0℃) | ||||

| Irradiation Intensity | (300~850nm) 550±10%W/㎡, (300~850nm) 1200±20%W/㎡ | |||

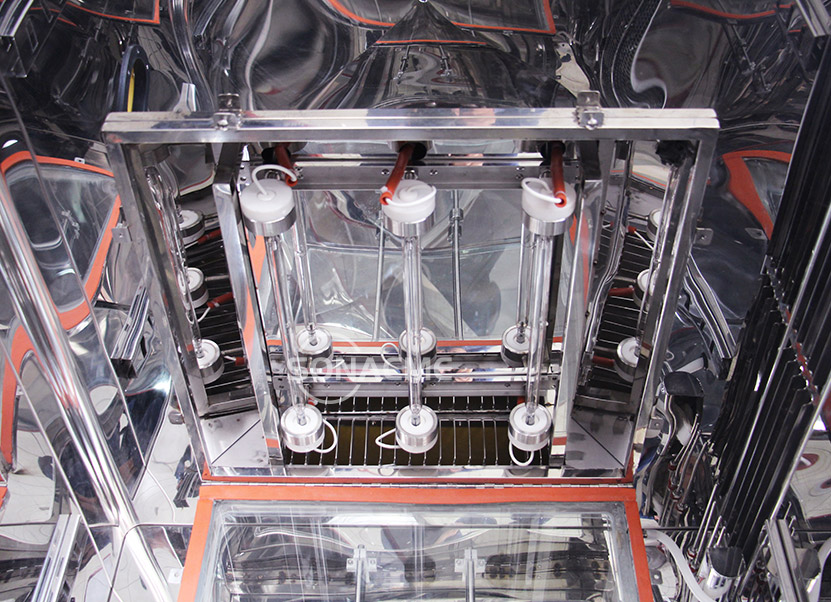

| Xenon Lamp Power | 3 pcs 1.8KW、2.5kw(Air-cooled full-solar and full-spectrum long-arc xenon lamp) | |||

| Power | 380V AC 50/60Hz | |||