The Drying oven is specially designed for your manufacturing process. These ovens are suitable for the production of automotive engineering, aerospace and electronic products, as well as the processing of various materials such as glass, ceramics, plastics, metals, textiles and composite materials.

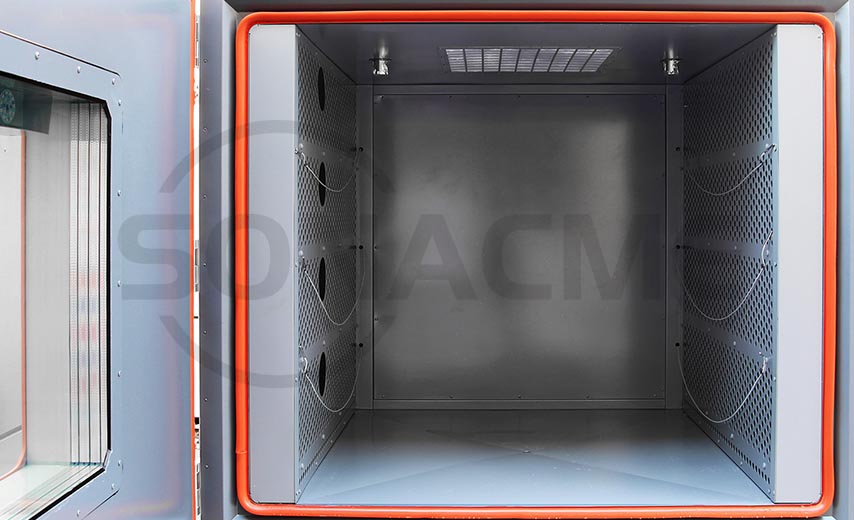

The precision high temperature test chamber achieves a very uniform temperature distribution through the directional air ducts in the processing space, ensuring reproducible production results.

The Drying oven provides the safety concept of primary and secondary explosion-proof measures for the safe heat treatment process in the fields of lithium-ion batteries, chemical, pharmaceutical, paint and basic materials industries.

The inner chamber material is made of SUS#304 stainless steel with 1.2mm thickness. Full welding structure, its sealing is very well and it’s not easy to get cracked.

The external material is made of cold-rolled plate with 1.5mm thickness, it has gone through brushing, polishing, painting treatment, it's not easy to get scratched.

The insulation material is made of polyurethane foam with thicknessof 100mm.

The door seal adopts double silicon rubber sealing material.

The observation window is 4 layers of tempered glass, the size you can choose by yourself.

In addition, in order to prevent frosting on the observation window when running low temperature, we setup a heating wires inside to get it di-frosting.

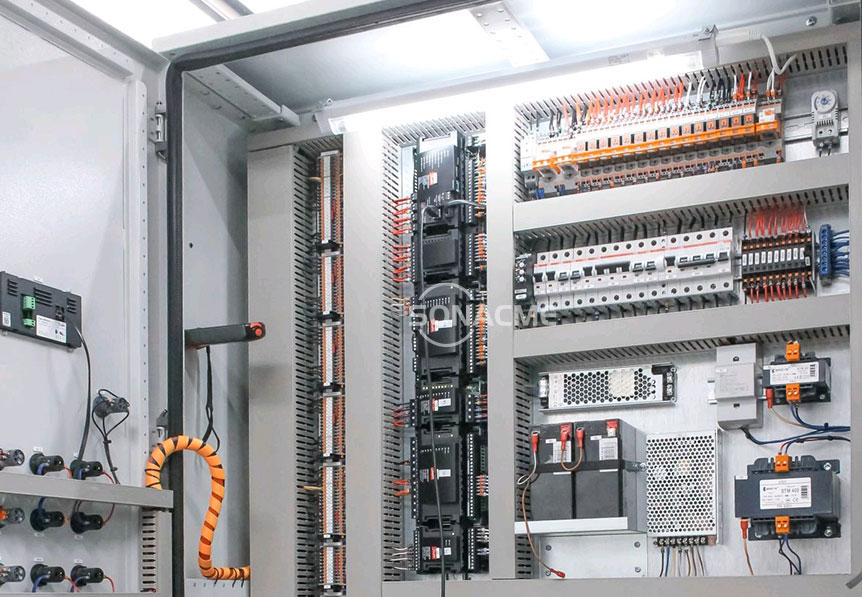

The overall layout of the circuit cabinet looks very neat and professional. Our circuits are arranged in accordance with UK standards and are equipped with complete circuit diagrams. Each line has a unique code which is clearly defined and easy to locate for troubleshooting.

We use electrical components of world famous brands, such as Schneider from France, Carlo Gavazzi from Switzerland,Mitsubishi from Japan,Rainbow from Korea.

| Model | SDO/1000/300 | SDO/1800/300 | SDO/2500/300 | SDO/3600/300 |

| Volume | 1000L | 1800L | 2500L | 3600L |

| Internal Dimension W*H*D(mm) | 1000*1000*1000 | 1000*1500*1200 | 1200*1500*1400 | 1200*2000*1500 |

| External Dimension W*H*D(mm) | 1200*1550*1450 | 1200*2000*1650 | 1400*2000*1850 | 1400*2350*1950 |

| Temperature Control Range | RT℃~300℃ | |||

| Temperature fluctuation | ±0.5℃ | |||

| Heating rate | 25.0℃~100.0℃ within 8 mins 6.0~10.0℃/min | |||

| Power supply | 380V AC 50/60Hz | |||