Application area

Sonacme Settling Dust Chambers simulates the damage of natural dust (sand, wind, dust, etc.) to products and materials, causing incalculable economic losses every year. The damage caused mainly includes corrosion, fading, deformation, strength decrease, swelling, mold, etc., especially electrical products are easy to cause fires due to short circuits caused by sand and dust. Therefore, it is an indispensable key procedure to conduct a dustproof test of the enclosure for a specific product or material.

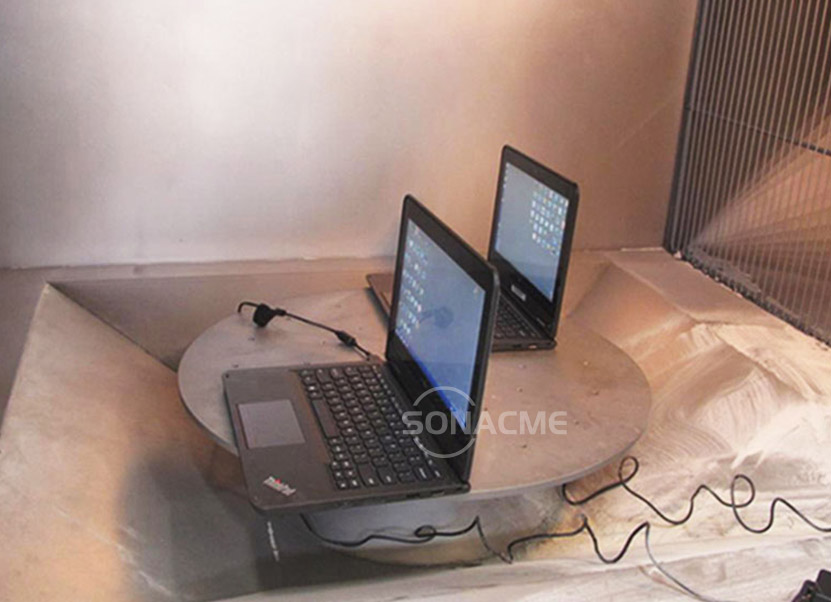

It is suitable for dust testing of outdoor lamps, household appliances, auto parts and other electronic and electrical products.

Sonacme Technology Sand and Dust Test Chamber complies with IEC60529:1989 +A1:1999 +A2:2013 "Degrees of protection provided by enclosures (IP Code)", GB4208-2008 "Enclosure Protection Level (IP Code)" 13.4, 13.5 clauses and diagrams 3 and GB7000.1 "Part of Lamps: General Requirements and Tests" 9.2.1, 9.2.2 and the requirements of Figure 6.

The inner chamber material is made of SUS#304 stainless steel with 1.2mm thickness. Full welding structure, its sealing is very well and it’s not easy to get cracked.

The external material is made of cold-rolled plate with 1.5mm thickness, it has gone through brushing, polishing, painting treatment, it's not easy to get scratched.

The insulation material is made of polyurethane foam with thicknessof 100mm.

The door seal adopts double silicon rubber sealing material.

The observation window is 4 layers of tempered glass, the size you can choose by yourself.

In addition, in order to prevent frosting on the observation window when running low temperature, we setup a heating wires inside to get it di-frosting.

The overall layout of the circuit cabinet looks very neat and professional. Our circuits are arranged in accordance with UK standards and are equipped with complete circuit diagrams. Each line has a unique code which is clearly defined and easy to locate for troubleshooting.

We use electrical components of world famous brands, such as Schneider from France, Carlo Gavazzi from Switzerland,Mitsubishi from Japan,Rainbow from Korea.

| Model | SSD/500 | SSD/1000 | SSD/2000 |

| Volume | 500L | 1000L | 2000L |

| Internal Dimension W*H*D(mm) | 800*800*800 | 1000*1000*1000 | 1000*2000*1000 |

| External Dimension W*H*D(mm) | 1450*1700*1000 | 1650*1900*1200 | 1650*2900*1200 |

| Dustfall form | Free fall dust type :The dust is blown to 1/5 of the tank top by centrifuge to make it free settling | ||

| Dust blowing:Bottom air blast , three grades pressure is adjustable | |||

| Standard configuration | With dust drying device, vibrator, sample holder, observation window (door) | ||

| Safety protection | Overload breaking protection, earthing protection, etc. | ||