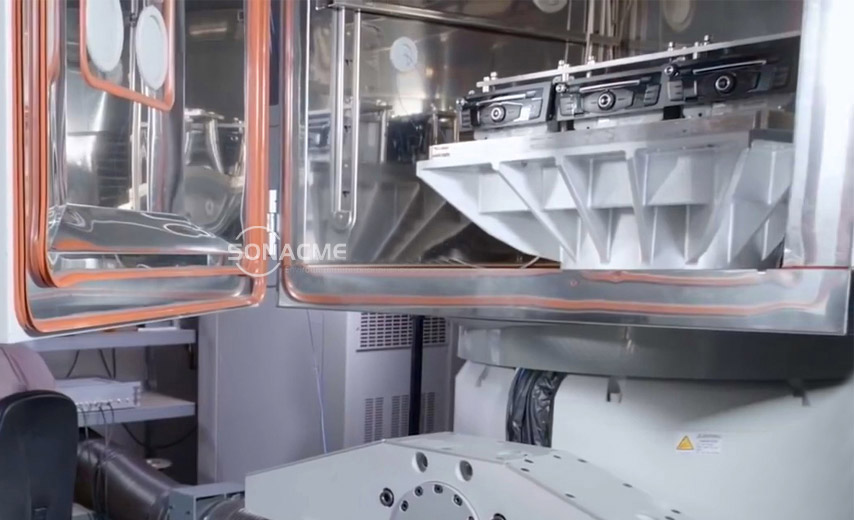

SONACME AGREE vibration test chamber can simulate the changes and damages of the three physical quantities of temperature, humidity and vibration to the product in the natural environment. The reliability of the product and the adaptability to the environment have been evaluated, so it can perform temperature and humidity changes and random vibration at the same time. Find out the limit points and product defects of the product.

AGREE vibration test chamber can test aviation, military products, vehicles, and electronic high-tech product test equipment. The combined constant temperature and humidity test box can make your quality reliability test closer to the test in the real environment.

Vibration testing control system capabilities: linear, logarithmic, and double frequency sweep.

EC60068-2-30、GJB150-09、JPCA-ET05、GB2423.4。

Wet freezing [low temperature cycle]IEC60068-2-38MIL-STD-202-106AECQ-200JPCA-ET06 \nJIS 5016-9.4GB2423.34

The inner chamber material is made of SUS#304 stainless steel with 1.2mm thickness. Full welding structure, its sealing is very well and it’s not easy to get cracked.

The external material is made of cold-rolled plate with 1.5mm thickness, it has gone through brushing, polishing, painting treatment, it's not easy to get scratched.

The insulation material is made of polyurethane foam with thicknessof 100mm.

The door seal adopts double silicon rubber sealing material.

The observation window is 4 layers of tempered glass, the size you can choose by yourself.

In addition, in order to prevent frosting on the observation window when running low temperature, we setup a heating wires inside to get it di-frosting.

Compressors equipped with world famous brand such as Tecumseh (France made), Bitzer or GEA BOCK (Germany made).

Shock absorption and noise reduction process,slow down the vibration, protect the compressor.

The new pipe bending technology: The bending process can minimize the connector point and make refrigerant flow more efficiently.

It applies Denmark DANFOSS and Japanese SAGLNOMIYA solenoid valves to improve the overall reliability of the equipment.

MP10 module has motor over-heating protection (with LED indicator), exhaust temperature over-heating protection (requires optional temperature monitoring probe and LED indicator), power indicator, alarm function.

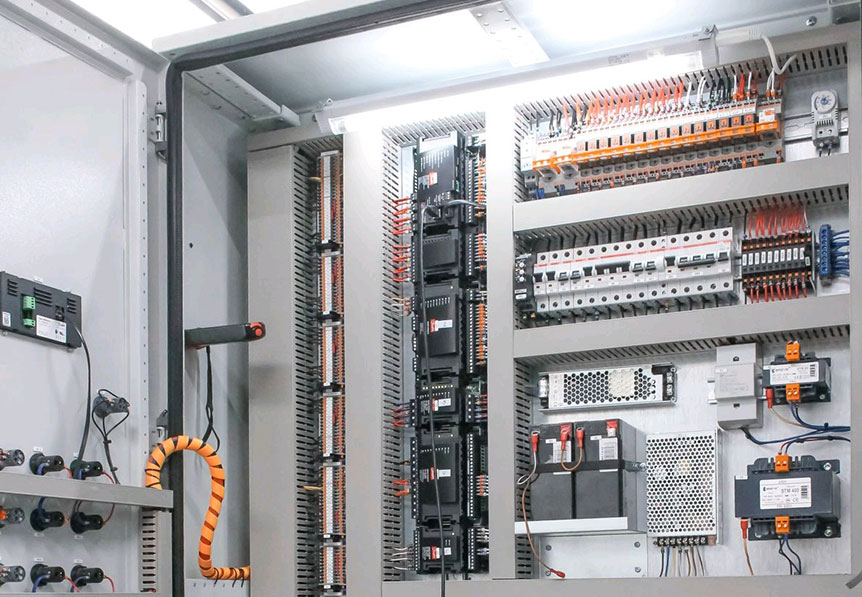

The overall layout of the circuit cabinet looks very neat and professional. Our circuits are arranged in accordance with UK standards and are equipped with complete circuit diagrams. Each line has a unique code which is clearly defined and easy to locate for troubleshooting.

We use electrical components of world famous brands, such as Schneider from France, Carlo Gavazzi from Switzerland,Mitsubishi from Japan,Rainbow from Korea.

| Model | SA/500/70(H) | SA/1000/70(H | SA/1700/70(H) | SA/3400/70(H) |

| Volume | 500L | 1000L | 1700L | 3400L |

| Internal dimensions W×H×Dmm | 800*800*800 | 1000*1000*1000 | 1200*1200*1200 | 1500*1500*1500 |

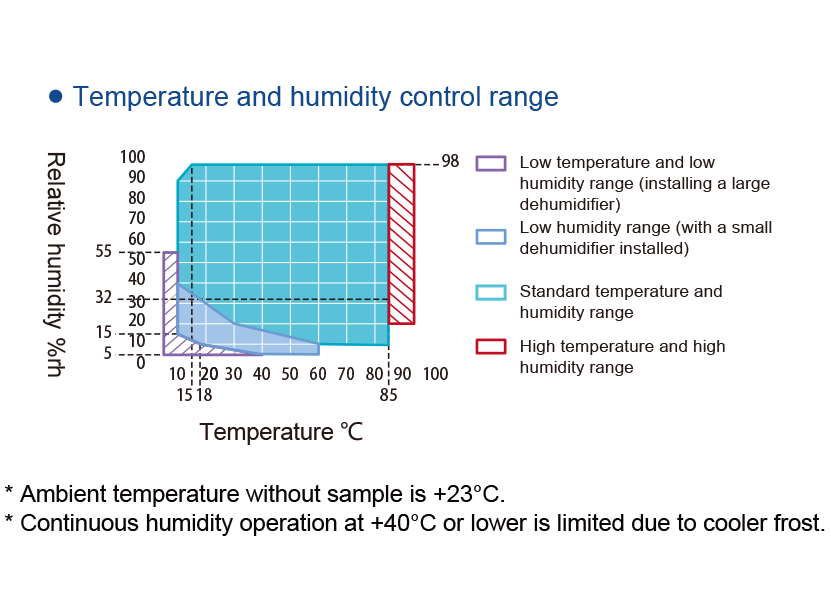

| Temperature&Humidity range | -70~+100℃ (+150℃/+180℃) / 20~95%rh | |||

| Temperature&Humidity fluctuation | ±0.5°C / ±2.0%rh | |||

| Temperature uniformity | 1.5°C | |||

| Temperature change rate | Heating rate:3.0°C/min Cooling rate:2.0°C/min | |||

| Power supply | 380V AC 50/60Hz | |||

| Controller | Standard: SONACME | |||