ASTM D1148 Rubber Testing - UV Lamp Weathering Test Chamber

Publish Time:2024-12-20Views:()

ASTM D1148 is a series of test standards issued by the American Society for Testing and Materials (ASTM International). Sonacme Technology's UV aging tester has high flexibility and adaptability in design and function, and can simulate a variety of natural environmental conditions, including UV radiation, temperature, humidity, etc., to meet the test requirements of ASTM D1148.

Overview of ASTM D1148

The ASTM D1148 standard is mainly used to evaluate the heat resistance, oxidation resistance and UV resistance of rubber materials. By simulating harsh environments such as high temperatures, oxidation and UV radiation, the standard can comprehensively test the changes in the performance of rubber materials under these conditions, providing an important basis for the production, material selection and quality control of rubber products.

Test Requirements for ASTM D1148

For evaluating the discolouration properties of white or light-coloured vulcanised rubber products, the ASTM D1148 standard specifies specific UV and thermal environmental conditions. These conditions typically include a certain relative humidity, haze, temperature, and intensity of UV or UV/visible light exposure. Under these conditions, rubber samples are subjected to a certain number of light cycles, and the degree of discolouration is then determined by comparing it to a comparison sample that is irradiated together. These tests help to understand the chemical stability of rubber materials in harsh environments.

Application Areas of ASTM D1148

The ASTM D1148 standard has a wide range of applications in a number of areas, including but not limited to:

Rubber product production: To provide guidance and assurance for the production of rubber products to ensure that they perform as expected under high temperatures, oxidation and other environments.

Material Selection: as the basis for material selection, to help users choose rubber materials that meet the expected performance.

Quality control: Used in the production and quality control of rubber materials to ensure that the rubber materials produced meet the expected performance requirements.

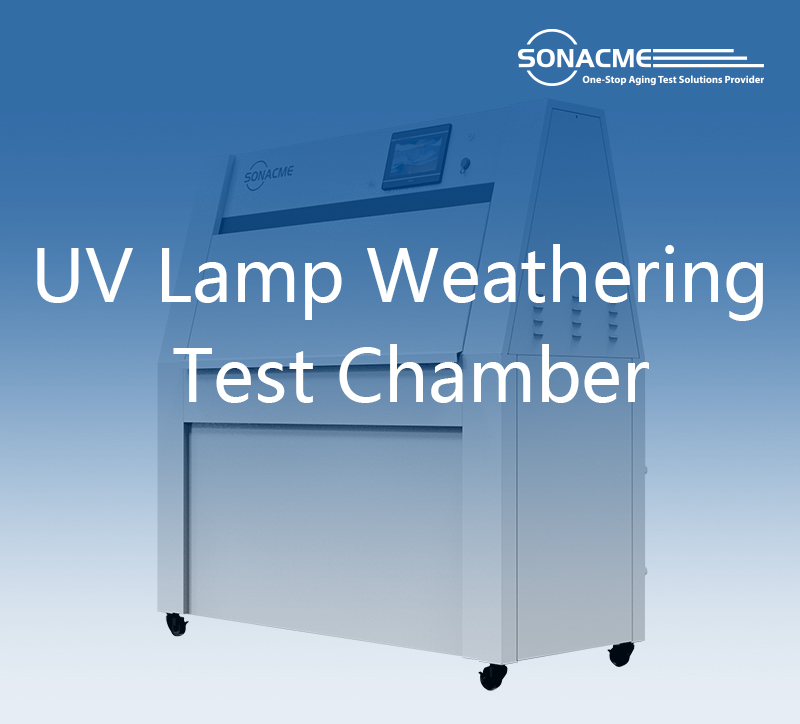

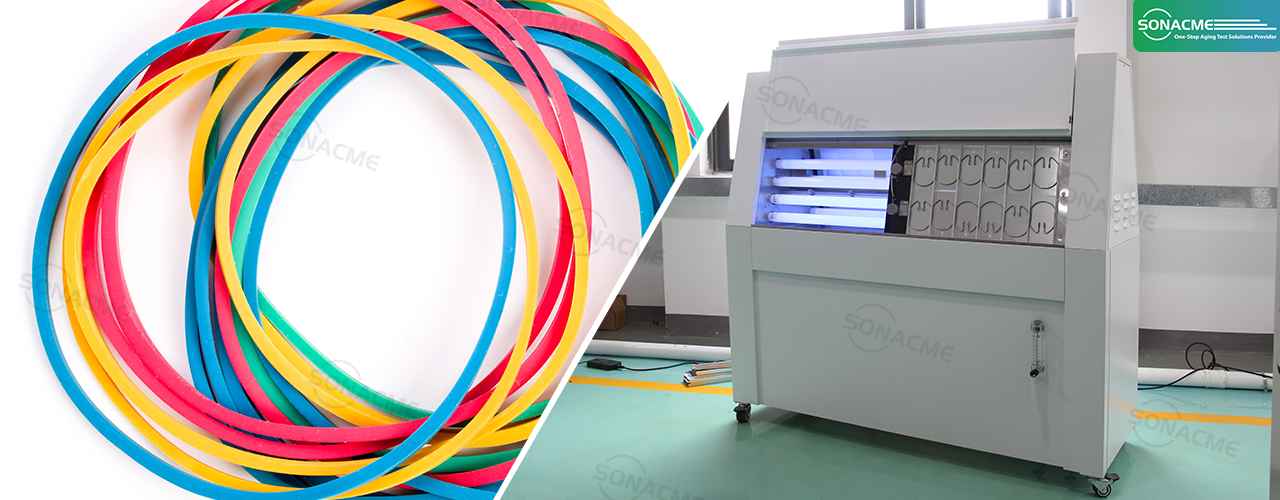

Parameters of Sonacme Technology UV Lamp Weathering Test Chamber

Sonacme Technology UV Lamp Weathering Test Chamber light source: UV-A (wavelength 340nm) or UV-B (wavelength 313nm); 40W × 8 (normal service life of 6000 hours)

Irradiance can be set range: 0.3 W/M2 ~ 1.55 W/M2

Blackboard temperature setting range: room temperature +10 ℃ ~ 80 ℃

Exposure area: 5175cm2/828in2

Standard sample plate: 24 standard sample plate racks (can be put 48 pieces of 150 × 70mm sample plate at a time)

Sonacme Technology's UV Lamp Weathering Test Chamber has controlled irradiation energy and temperature throughout the test cycle. A typical test cycle is usually a UV UV irradiation at high temperature and a dark humid condensation cycle with relative humidity at 100%; it can be applied in paint and coating, automotive industry, plastic products, wood products, glue and other industries.

Sonacme Technology's UV Lamp Weathering Test Chamber meets the ASTM D1148 rubber test standard is a reliable aging test equipment, can meet the accelerated aging test needs of plastic, paint and other products. If you would like to know more details,please feel free to contact us.

Latest News

-

MIL-STD-2164 Rapid Temperat...

ASTM D1148 is a series of test standards issued by t...

-

JPCA-ET05 High-Low Temperat...

ASTM D1148 is a series of test standards issued by t...

-

ISO 24444 Cosmetic Stabilit...

ASTM D1148 is a series of test standards issued by t...

-

EC60068-2-30- SONACME Techn...

ASTM D1148 is a series of test standards issued by t...

-

Bench-top UV Light Accelera...

ASTM D1148 is a series of test standards issued by t...

-

ASTM G154 UV Lamp Weatherin...

ASTM D1148 is a series of test standards issued by t...

+86-180 2704 9206

Tel:+86(0769)83234966

E-Mail:info@sonacme.com

Contacts:Marcia/+86-180 2704 9206

Add:Building 7, No.310 Songbai Road, Liaobu Town, Dongguan City, Guangdong

+86-180 2704 9206

+86-180 2704 9206 WhatsApp:+86-180 2704 9206

WhatsApp:+86-180 2704 9206 info@sonacme.com

info@sonacme.com