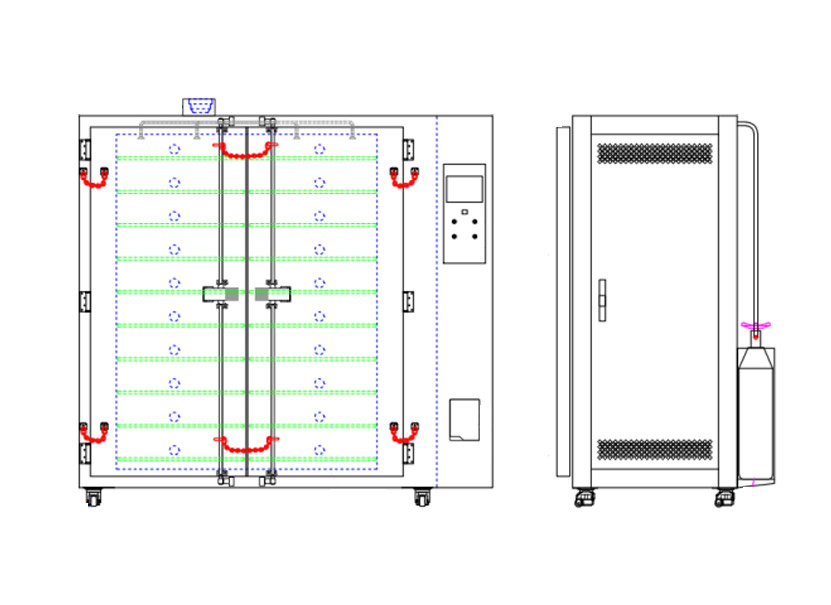

Battery Cell Oven

Application area

The precision high temperature test chamber is specially designed for your manufacturing process. These ovens are suitable for the production of automotive engineering, aerospace and electronic products, as well as the processing of various materials such as glass, ceramics, plastics, metals, textiles and composite materials.

The precision high temperature test chamber achieves a very uniform temperature distribution through the directional air ducts in the processing space, ensuring reproducible production results.

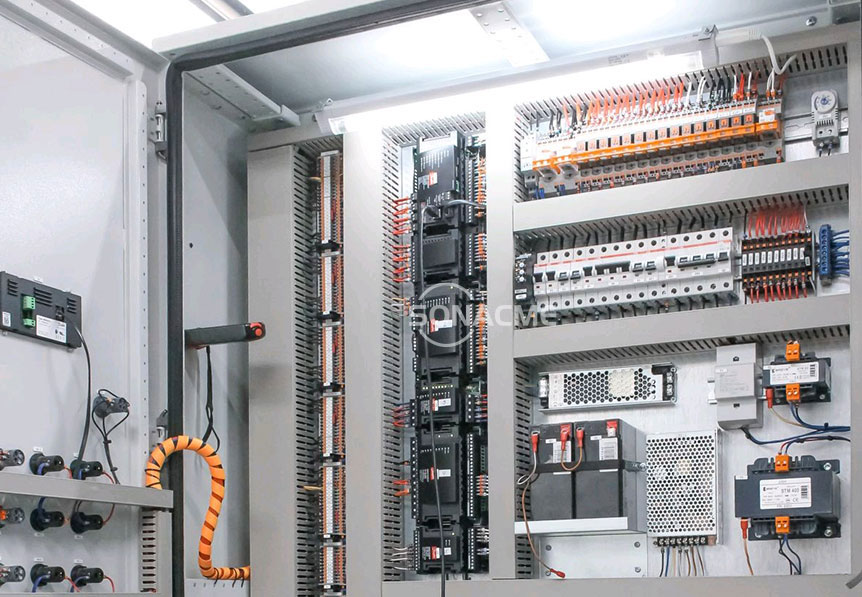

The high temperature test chamber provides the safety concept of primary and secondary explosion-proof measures for the safe heat treatment process in the fields of lithium-ion batteries, chemical, pharmaceutical, paint and basic materials industries.

+86-180 2704 9206

+86-180 2704 9206 WhatsApp:+86-180 2704 9206

WhatsApp:+86-180 2704 9206 info@sonacme.com

info@sonacme.com