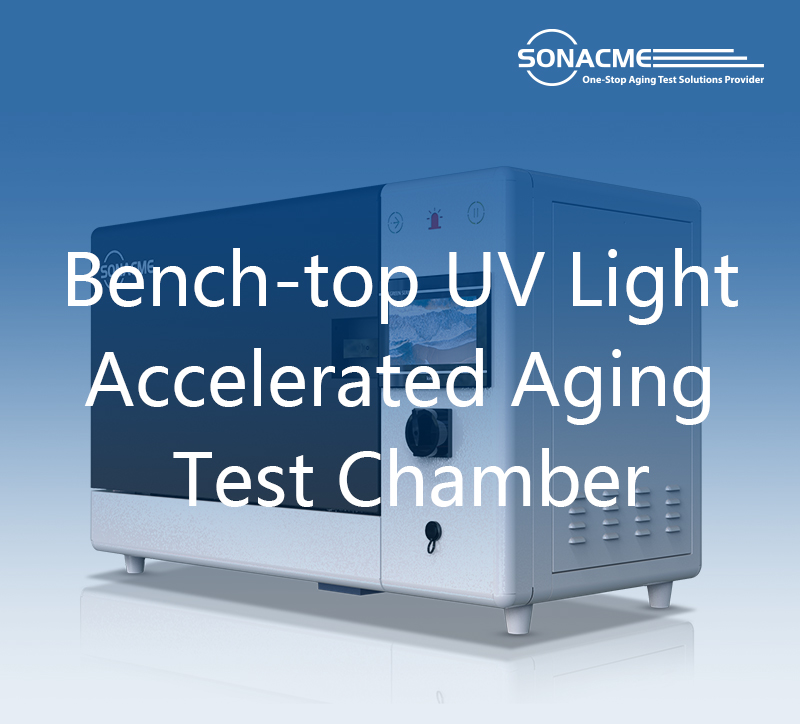

ISO 4892-3 Testing of plastics - Bench-top UV Light Accelerated Aging Test Chamber

Publish Time:2025-01-04Views:()

ISO 4892-3 Plastics - Methods of exposure to laboratory light sources - Part 3: Fluorescent ultraviolet lamps, is a standard developed by the International Organisation for Standardisation (ISO) for light aging tests on plastics under fluorescent ultraviolet lamps.

Overview of the Standard

The ISO 4892-3 standard is part of the ISO 4892 series of standards and is dedicated to the specification of methods for light ageing tests on plastics using fluorescent ultraviolet lamps. The purpose of the standard is to assess the light stability of plastic materials by performing reproducible light ageing tests under standardised test conditions.

Sonacme Technology Bench-top UV Light Accelerated Aging Test Chamber Parameters

Total power: 1.2 KW

Lamp irradiation energy (new): 0.9W/M2 (UVA); 0.7W/M2 (UVB)

Wavelength: 313nm (or 340nm)

Rated lamp life: 1000h

Lamp wall to the nearest distance to the specimen: 50 mm

Light source and Radiation characteristics

Sonacme's Bench-top UV Light Accelerated Aging Test Chamber use fluorescent UV lamps as the light source, which meets the requirements of ISO 4892-3 for the type of light source. Sonacme's Bench-top UV Light Accelerated Aging Test Chamber is able to simulate the UV portion of global solar radiation, especially the UV-A (340nm) or UV-B (313nm) light source types, which helps to reduce the UV irradiation that raw materials are exposed to in real-world application environments. At the same time, the irradiance of the tester can be set between 0.3 W/m2 and 1.55 W/m2, which meets the requirements of the standard for radiation intensity.

Temperature and Humidity Control

The ISO 4892-3 standard specifies methods for exposing specimens to fluorescent UV radiation, heat and water. Sonacme technology's Bench-top UV Light Accelerated Aging Test Chamber is equipped with an advanced temperature and humidity control system to simulate humidity changes under different climatic conditions. The black panel temperature setting range is between room temperature +5℃~+60℃, which helps to evaluate the stability of materials under different temperature conditions. In addition, the tester is equipped with a spray and condensation system that simulates the effects of a humid environment on the material.

The purpose of the ISO 4892-3 standard is to assess the light stability of plastic materials by performing reproducible light ageing tests on them under standardised fluorescent UV lamp aging conditions. The standard is mainly applied to experimental research and quality control testing of light ageing of plastics, coatings, adhesives and other materials. Through this standard, the effect of different light stabiliser additives can be evaluated, and the best additive formulation can be selected to improve the service life of plastic products.

Sonacme's Bench-top UV Light Accelerated Aging Test Chamber meets the requirements of ISO 4892-3 standard in terms of light source and radiation characteristics, temperature and humidity control, test parameters and performance evaluation, etc. It is an important tool for assessing the weathering and aging stability of materials. If you need to know more details, you can contact us at any time.

Latest News

-

MIL-STD-2164 Rapid Temperat...

Sonacme's Bench-top UV Light Accelerated Aging Test ...

-

JPCA-ET05 High-Low Temperat...

Sonacme's Bench-top UV Light Accelerated Aging Test ...

-

ISO 24444 Cosmetic Stabilit...

Sonacme's Bench-top UV Light Accelerated Aging Test ...

-

EC60068-2-30- SONACME Techn...

Sonacme's Bench-top UV Light Accelerated Aging Test ...

-

Bench-top UV Light Accelera...

Sonacme's Bench-top UV Light Accelerated Aging Test ...

-

ASTM G154 UV Lamp Weatherin...

Sonacme's Bench-top UV Light Accelerated Aging Test ...

+86-180 2704 9206

Tel:+86(0769)83234966

E-Mail:info@sonacme.com

Contacts:Marcia/+86-180 2704 9206

Add:Building 7, No.310 Songbai Road, Liaobu Town, Dongguan City, Guangdong

+86-180 2704 9206

+86-180 2704 9206 WhatsApp:+86-180 2704 9206

WhatsApp:+86-180 2704 9206 info@sonacme.com

info@sonacme.com